It’s been a while since my last update. I haven’t posted due changing jobs and lack of free time. The major upgrade has been a bit of a disappointment. I have not been able to reach the desired 11psi boost pressure at high engine RPM. I have managed to up the boost pressure to 10psi but only for short periods before the speed controllers’ trip on thermal overload. The below video shows what 10psi electric boost looks like but you will also see the system trip at the end of the run.

To try and explain the issue let’s take the following operating point:

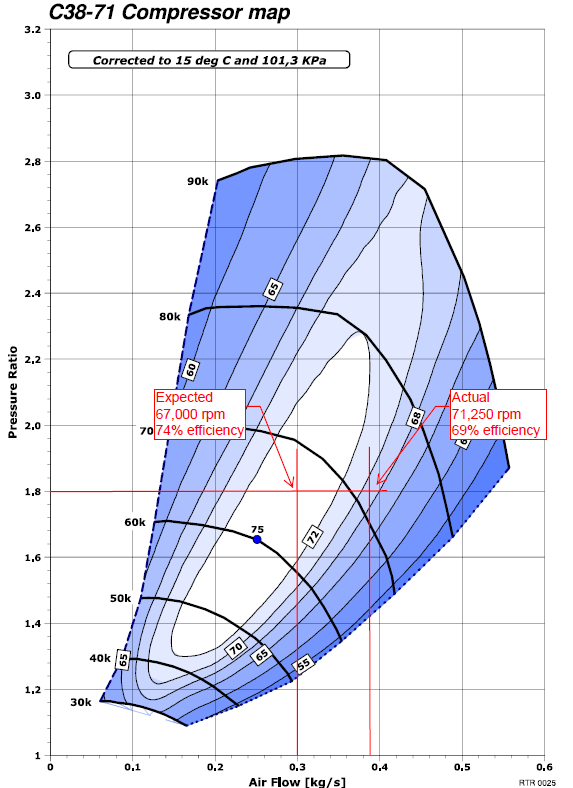

- Mass air flow = 0.3 kg/s (measured by the MAF sensor) at 7,500 rpm on the internal combustion engine

- Pressure ratio = 1.8 (10 psi measured at the MAP sensor with a 2 PSI pressure drop across intercooler and charge pipe)

At this operating point the new compressor should be right on the middle of the efficiency island with impellor spinning at 67,000 rpm and the electric motors consuming 25.5 kW of electrical power (see below compressor map).

But looking at the data, in reality the impellor is spinning at 71,250 rpm and the electric motors consuming 36 kW of electrical power. The only way this makes sense at this pressure ratio is if the mass flow is much higher (closer to 0.39 kg/s) or the actual pressure at the outlet of the compressor is much higher. The higher power consumption means higher current and leading to thermal overload of ECS’s and electric motors.

So, the question is what is going on? Below are potential causes and corresponding fault finding conducted:

- Boost leak between compressor and engine – thorough leak test of pipework conducted with no leaks of consequence found

- Higher than expected differential pressure across intercooler – differential pressure measured and found to be as expected (~2 psi)

- Manifold air pressure reading incorrect – reading has been confirmed against another sensor

- Compressor recycling – recirc valve was removed and capped, not change

- Lower than atmospheric pressure at compressor inlet – inlet pressure measured with vacuum gauge and no issue found

So, I am at a loss. I contacted Rotrex support, and they recommended creating a warranty claim and send the C38-71 back to them for inspection.