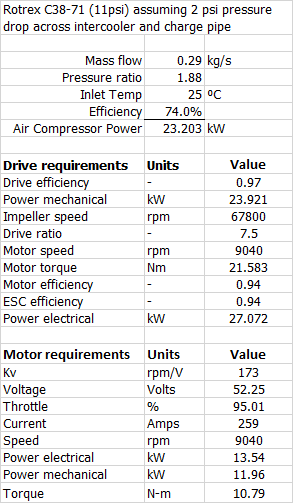

From the data collected so far, I now have a accurate mathematical model for calculating the required mechanical power, electrical power, and motor voltage/current to turn a centrifugal compressor at any combination of pressure ratio, mass air flowrate, impellor speed, and compressor adiabatic efficiency. The decision was made to size the new compressor for maximum efficiency at the maximum operating point thus maximizing the available electrical power. After modelling the Rotrex C38-71 was selected for the upgrade.

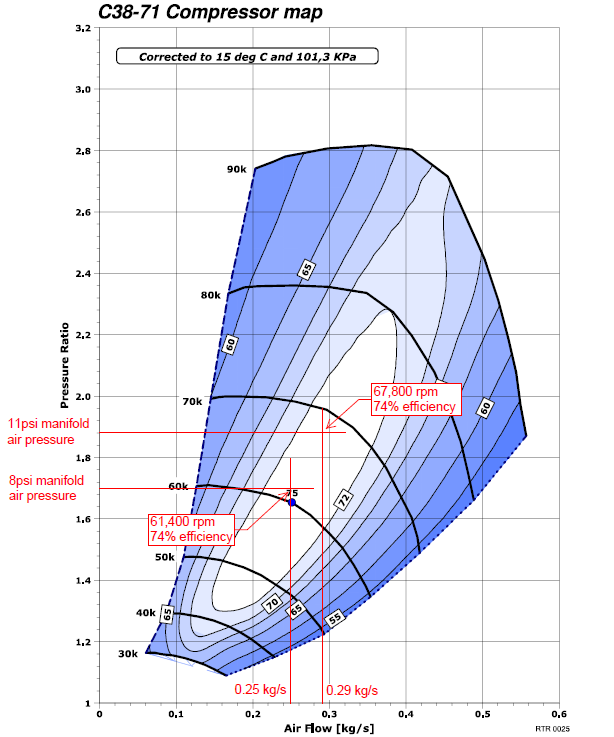

Below is the compressor map for the new C38-71 supercharger showing the 8 psi and 11 psi operating points.

The only issue with sizing the compressor for peak efficiency at max boost and max mass air flow is open throttle compressor surge at lower engine speeds. If this becomes an issue, I have some plans to mitigate.

Below is a side by side photo of the C30-84 and C38-71. There is a considerable size difference.

The C38-71 also has a different planetary gearbox with a lower ratio of 1:7.5 compared to the C30-84 at 1:9.49. Two new Lehner Torqstar 7050 motors were ordered with different winding turn count to best suit the new compressor. Below are the sizing calculations for the new motors.

As before these a liquid cooled units but in the industrial application construction which allows lugged connections to be used for phase cables.

And as before the motors were combined onto a common 12mm drive shaft in a back to back configuration.

New new plates were designed, drafted and CNC machined out of 10mm thick 6061 Aluminium to suit the new setup.

The complete unit looks much the same but the only carry over parts are the standoffs and torque tube halves. The drive coupler between the compressor and electric motors was upgraded to a L075 jaw coupler as the previous L070 coupler was chewing up the spider element due to operating above its rated torque level.