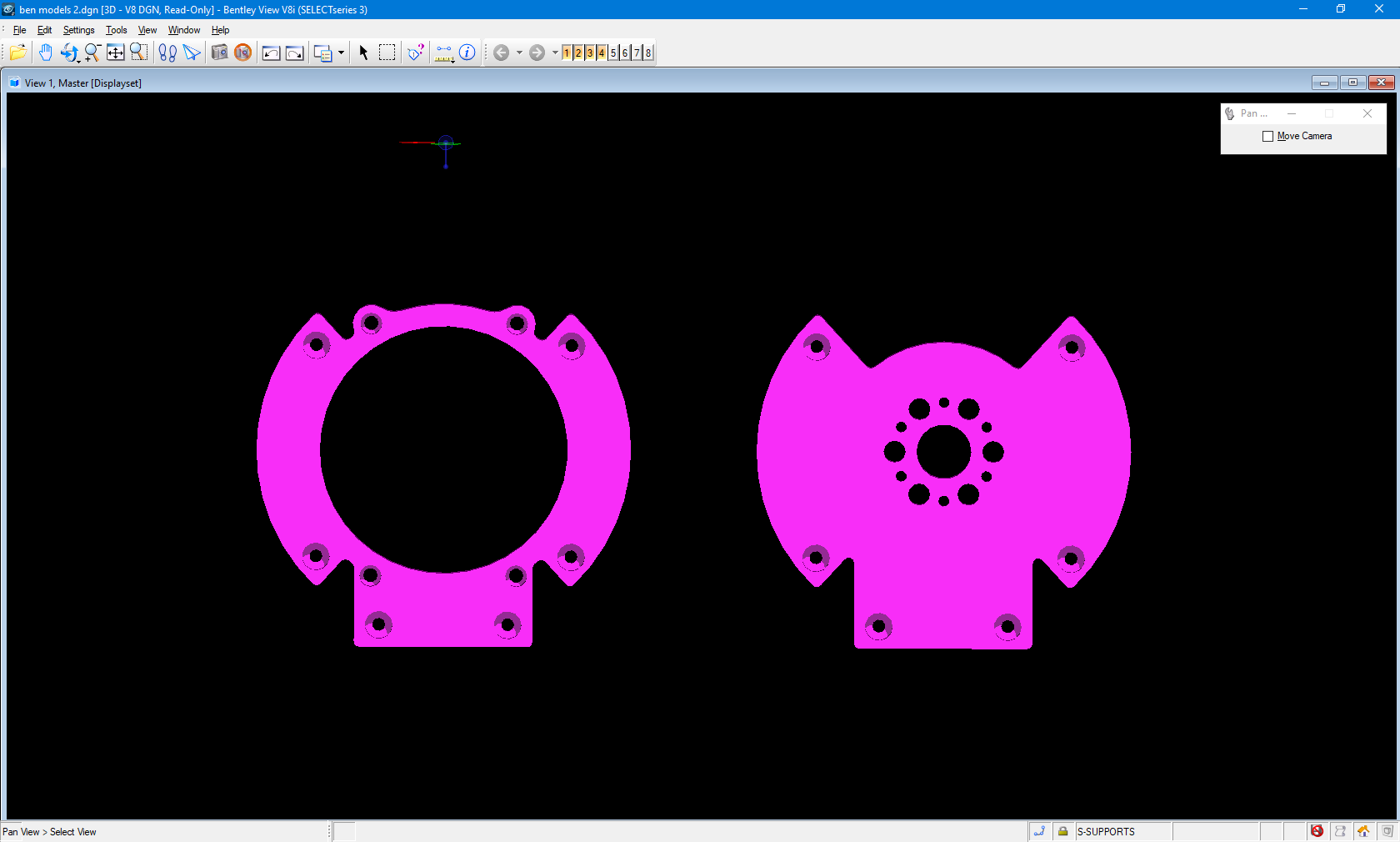

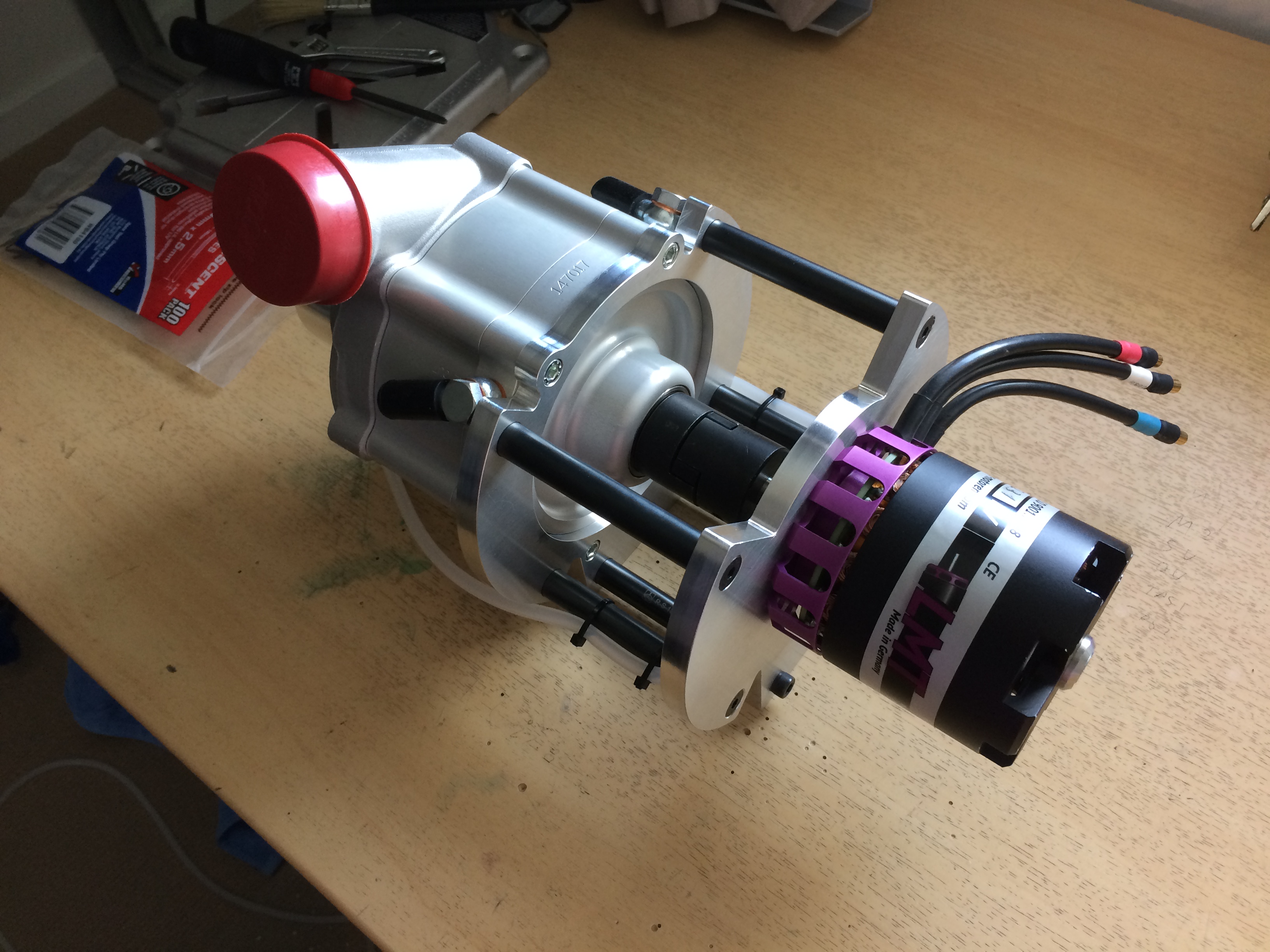

The plan from the start of the project was for the motor to direct drive the compressor. The selection of the Rotrex compressor and LMT motor electric motor made this possible. The next step was to design a system to connect the two so that the motor could drive the compressor. For power transmission the L Type standard jaw coupling was selected. Then mounting plates were designed to adapt the motor to the supercharger and also provide a means for mounting the assemble in the vehicle.

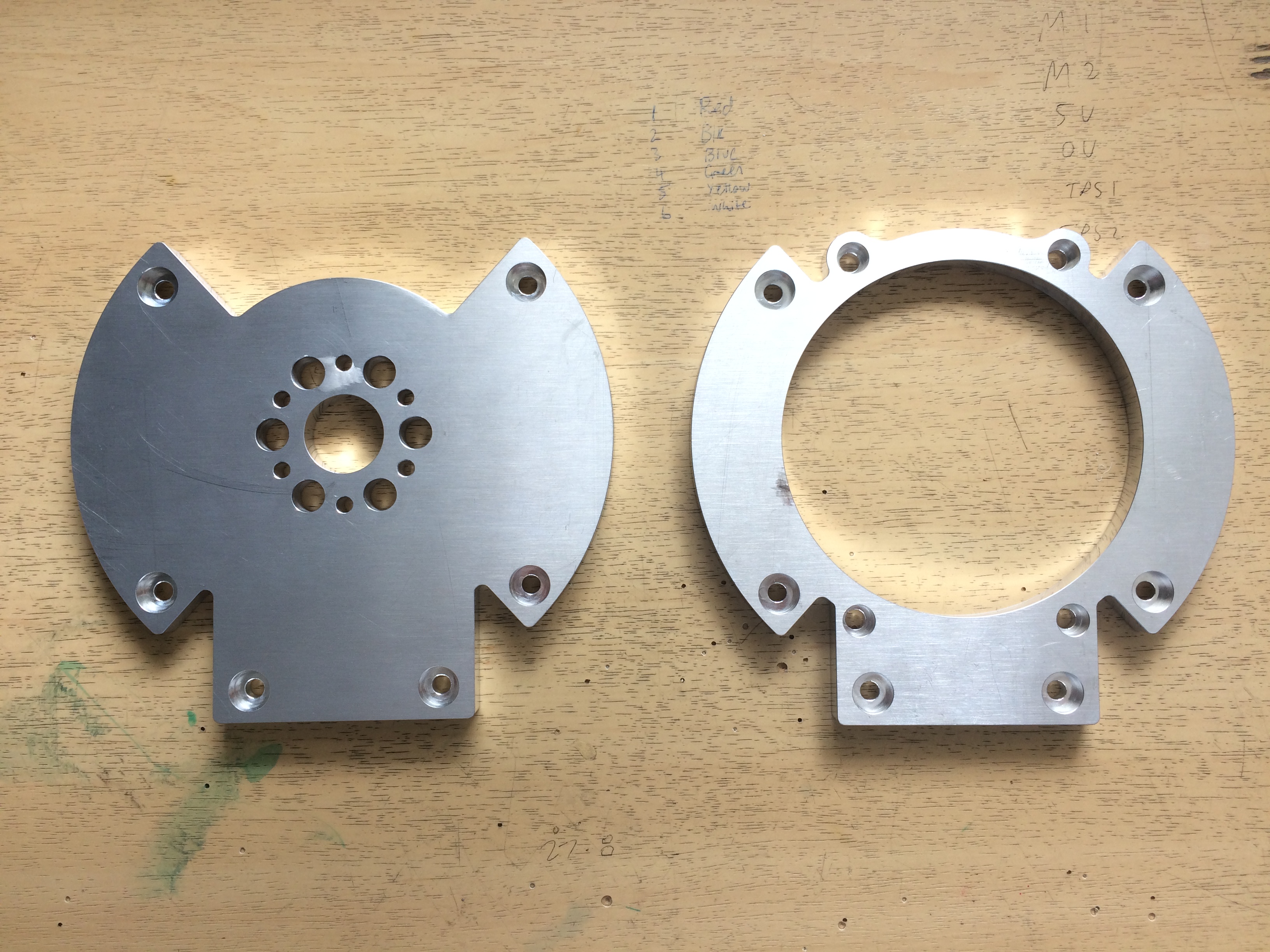

Mounting plates were machined from 10mm thick 6061 Aluminium plate. The six stand offs between the two plates are made of hardened steel and counter sunk for additional strength.

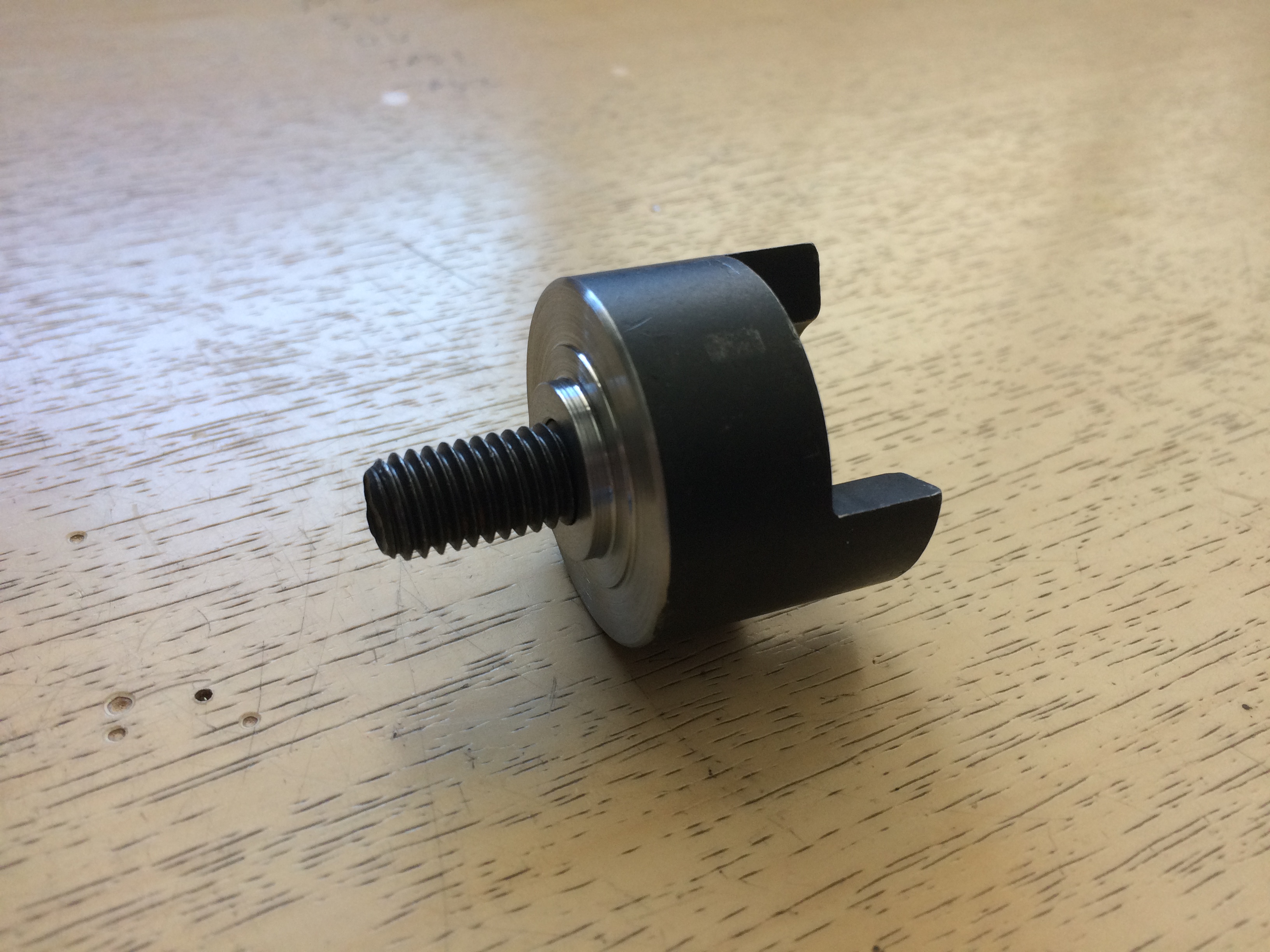

Modified L-type coupling

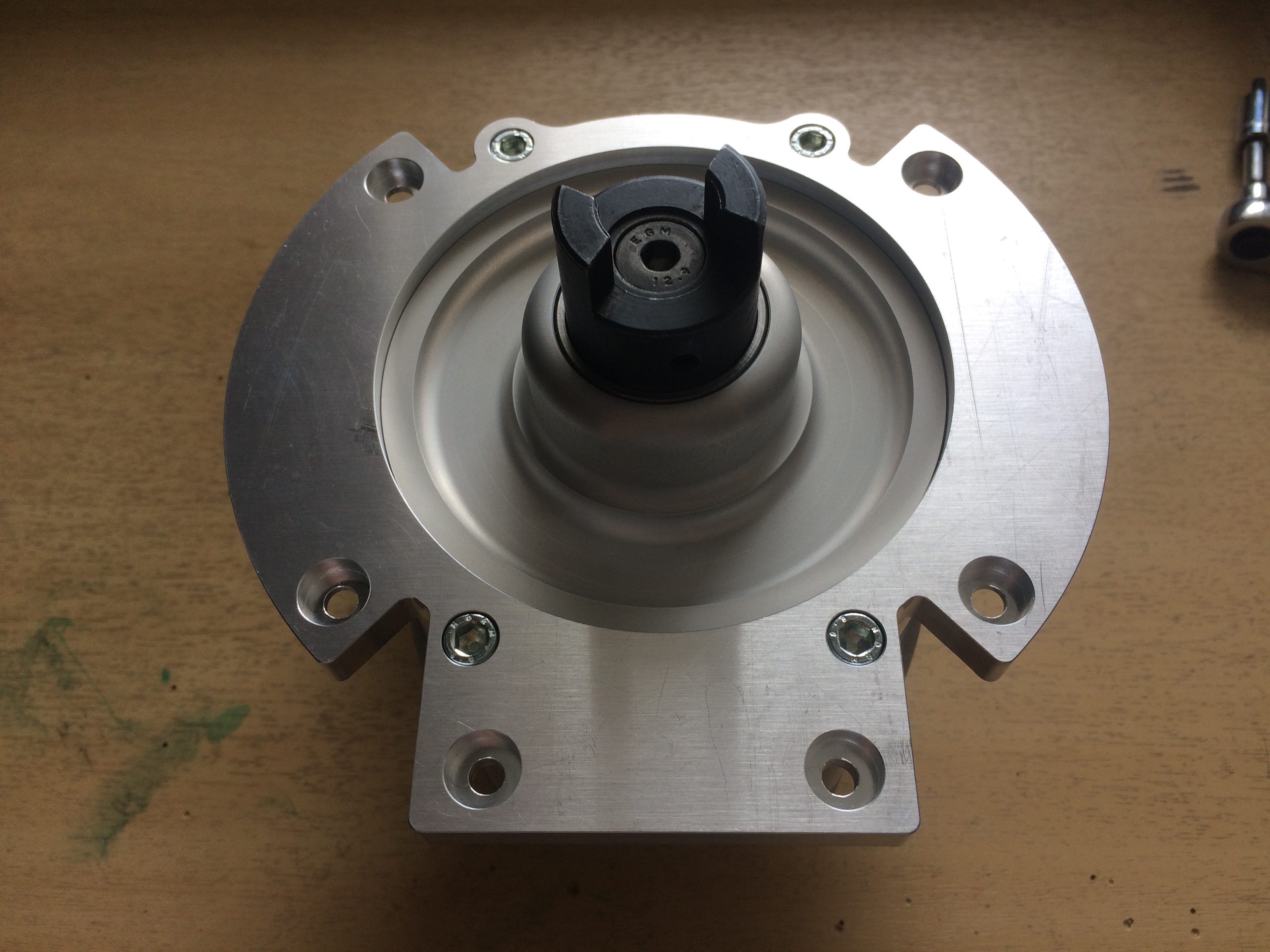

Coupling jaw installed on compressor

Compressor mounting plate

Steel standoffs

Electric motor mounting plate

Finished assemble

Final mass of the electric supercharger assemble is 8.5 kg.