The mention of electrical superchargers conjures up thoughts of the dodgy offerings on ebay. From initial calculations, 10 kW of mechanical power (equalling 12 kW of electrical power) would be required from the electric motor to produce 8.0 psi at redline and full load (this equates to a mass air flow of 2.55 g/s).

The problem with almost all electric supercharger systems currently available is voltage. That is running the electric motor of the vehicles 12 V battery. To generate 12 kW (16 HP) at 12 V requires 1000 A. This is not practical so voltage must be increase. For this project a battery voltage of 60 V was selected.

Next step was to select a motor. The motor had to be small and light with a high power to weight ratio. The Lehner Motoren Technik (LMT) Torqstar 3 was selected. LMT are a company out of Germany that design and manufacture the highest quality brushless DC electric motors. LMT Torqstar motors are hand made to order in one of 37 different winding configurations. This allowed the motor operating RPM range to be match perfectly to the required operating speed of the compressor. The motor was ordered with water cooling option to keep temperatures in check.

The selected winding of the LMT Torqstar 3 is rated for a maximum current of 290 amps giving a maximum electrical power input of approximately 15 kW and weighs in at 1.9 kg.

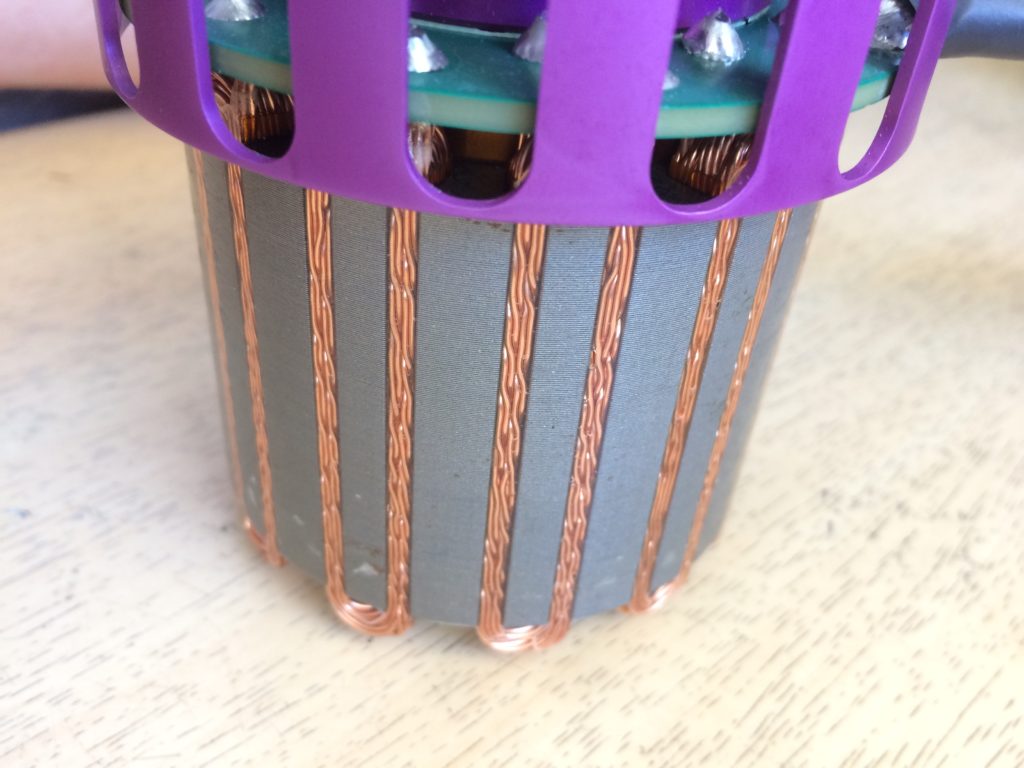

Had to take the motor apart to have a look. The stator core has a super fine laminations. It looks like the windings are pressed into rectangular stator slots held in place by the resin. The individual windings are then connect together using a PCB. The rotor is 20 pole (10 pairs of magnets).