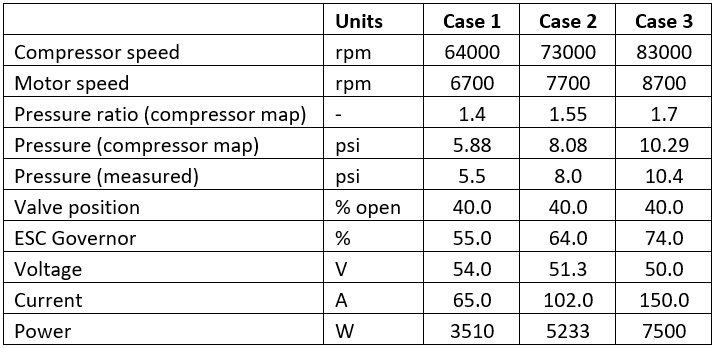

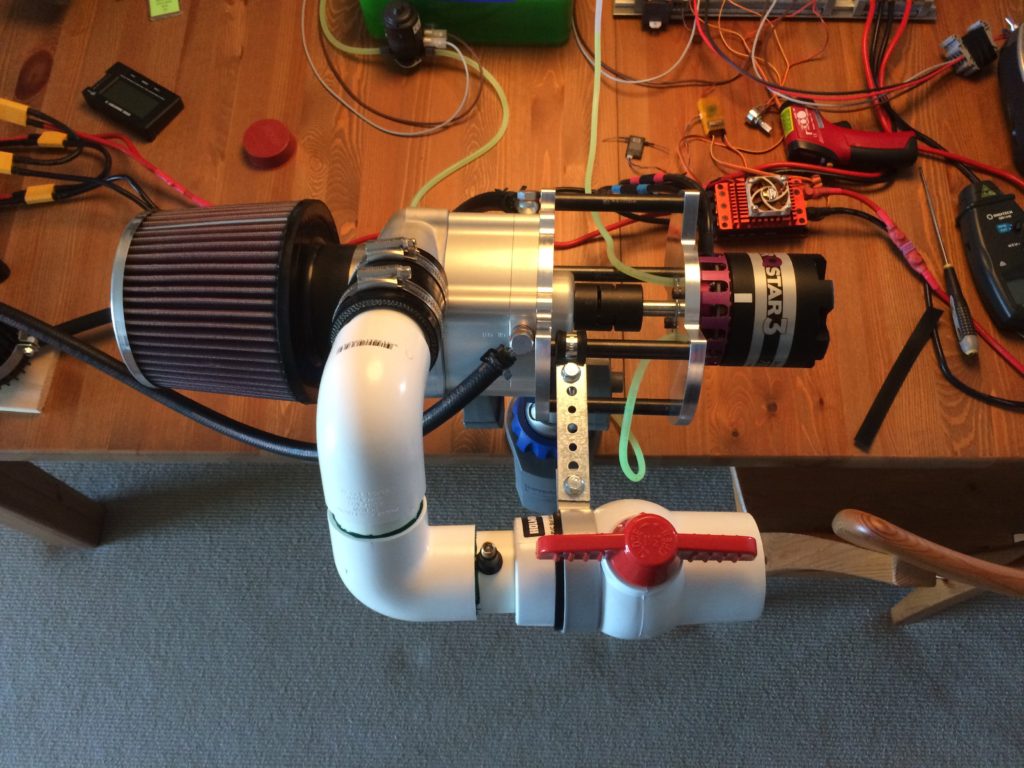

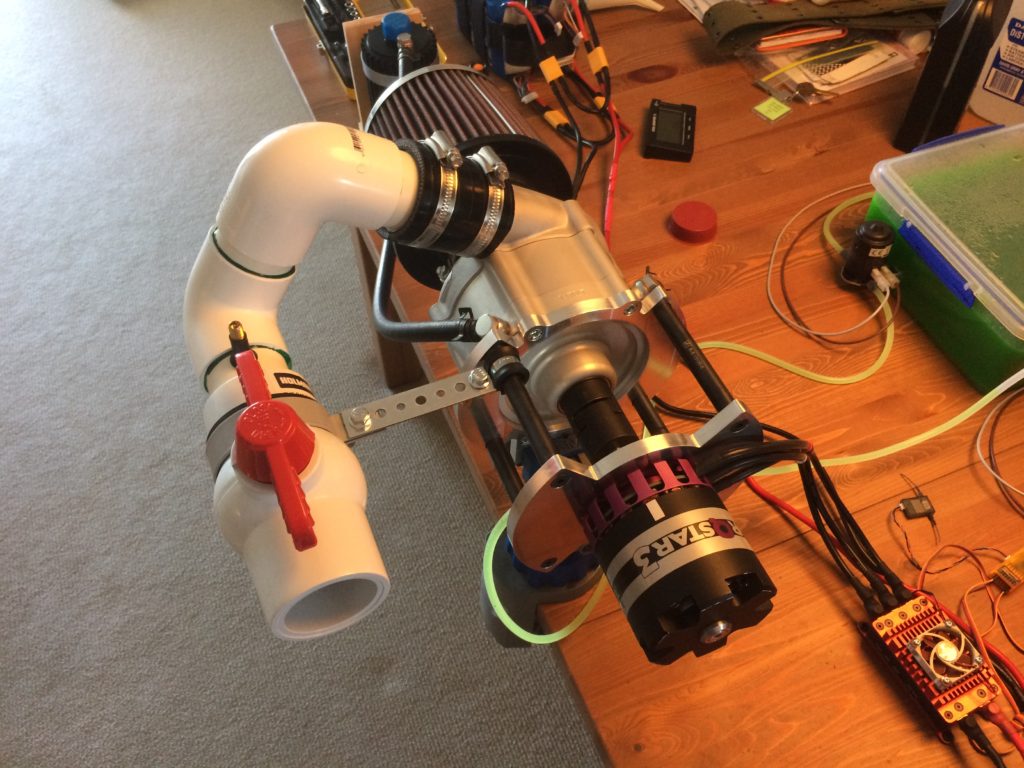

Initial bench testing (on the dining table) was conducted before committing to the installation of the system into the car. A PVC DN40 ball valve was adapted to the supercharger outlet so that backpressure onto the compressor could be manipulated. A tyre valve was installed between the compressor and the ball valve so boost pressure could be measured.

This testing was done to:

• Setup and test electronic speed controller

• Test operation of electric motor

• Test control system

• Test battery charging circuit

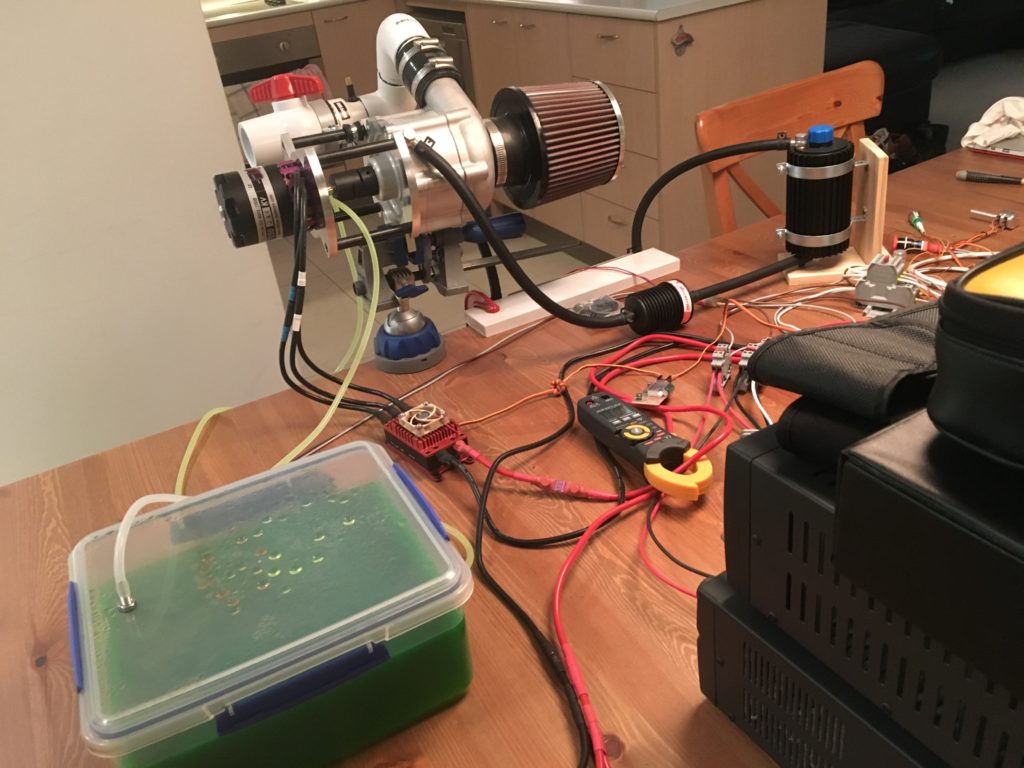

• Measure voltage, current, impellor speed, and boost pressure at different operating points

During testing a maximum of 10.4 psi was measured at the outlet of the compressor at a impellor speed of 83,000 rpm. Unfortunately, I did not have a means of measuring mass air flow. Below is data from bench testing.